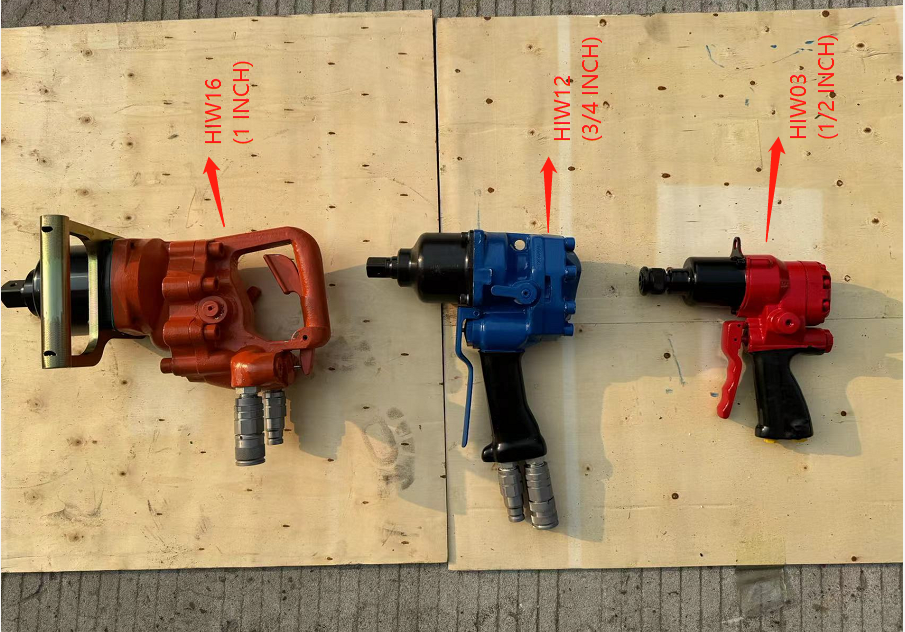

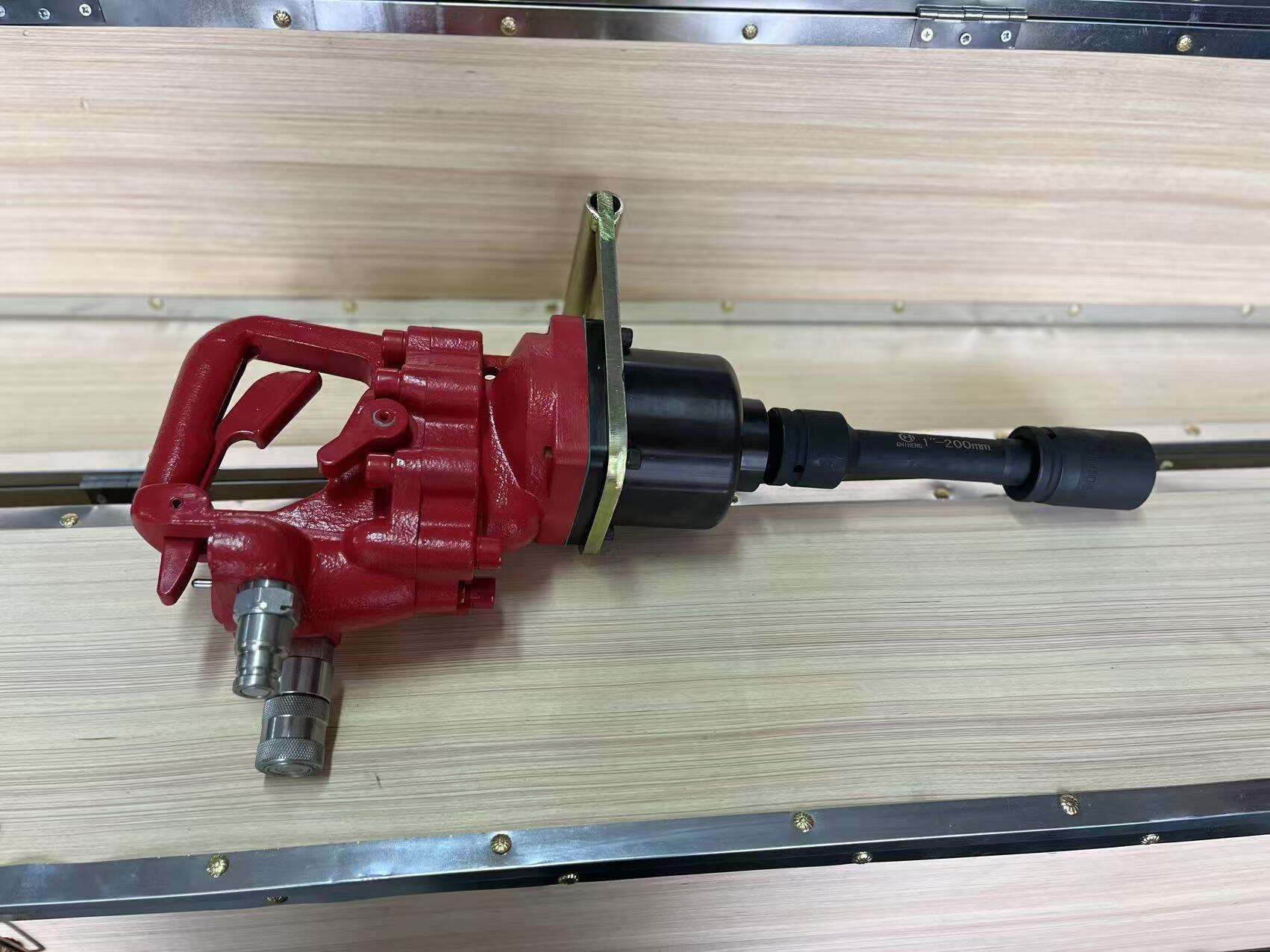

Hydraulic Wrench: Tool for High-Torque Bolt Operations

A hydraulic wrench is a tool that uses hydraulic power to generate high torque for tightening and loosening bolts. It is often used in large mechanical equipment installation and maintenance, as well as in construction projects where high-strength bolts need to be handled. DECKWELL's hydraulic wrenches offer advantages like large torque output, easy operation, and high work efficiency, enabling fast and accurate bolt operations.

Get A Quote