The Role of Hydraulic Breakers in Modern Road Maintenance

Understanding the hydraulic breaker and its core function in infrastructure projects

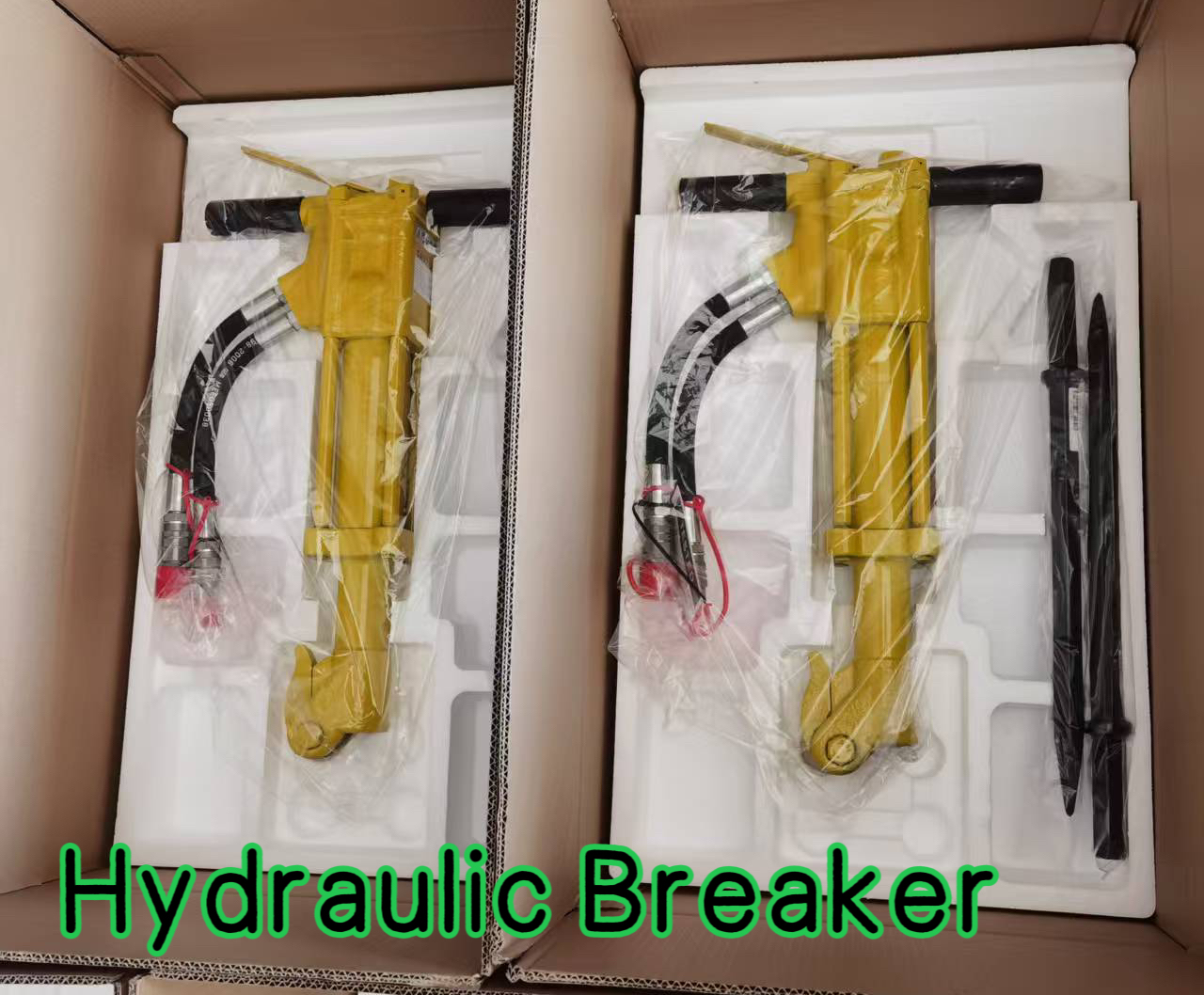

Hydraulic breakers take the hydraulic power from construction machines and turn it into powerful impacts that can tear through old asphalt and even tough reinforced concrete. According to some recent research by Ponemon in 2023, these machines actually penetrate materials about 25% better with each hit compared to what workers can do manually. That's why they're so important when taking apart road surfaces or getting the ground ready for new work. The way these breakers are built lets them attach right onto excavators, which cuts down on how many different pieces of equipment a company needs to buy. Plus, they pack quite a punch relative to their size, something that makes all the difference in tight city environments where space is at a premium.

Why road maintenance demands high-performance tools like the hydraulic breaker

Roads that are falling apart need fixing sooner rather than later before those small cracks turn into huge repair bills. The numbers back this up too hydraulic breakers get demolition jobs done about 40 percent quicker than old fashioned jackhammer teams, as found in a recent 2024 study on road maintenance efficiency. And when roads get fixed faster, there's less time for traffic jams to form something city officials worry about since it shows up in nearly 8 out of 10 infrastructure surveys they conduct. Plus these machines actually save money on fuel too. They transfer energy better so they burn through 18% less gas compared to the older air powered systems. That kind of efficiency makes them pretty good for both pocketbooks and the environment in the long run.

Comparing traditional methods to hydraulic breaker applications for road upkeep

| Method | Daily Output (sq.yd) | Labor Hours | Material Waste (%) | Noise Level (dB) |

|---|---|---|---|---|

| Manual Jackhammers | 120 | 14 | 28 | 105 |

| Hydraulic Breakers | 520 | 7 | 9 | 88 |

Hydraulic systems cut down on the hassle of setting up multiple pieces of equipment, which can slash mobilization expenses by around 34% for each project. According to research from 2023 looking at road maintenance teams across different states, crews working with hydraulic breaker attachments finished shoulder repair jobs approximately 2.1 days quicker compared to teams still using separate rock drilling machines. The time savings really matter during those urgent repairs needed after freeze-thaw cycles damage roads, especially since many areas face winter road closures that disrupt traffic flow and local economies.

Mechanical Principles Behind Hydraulic Breaker Efficiency

How Hydraulic Power Translates Into High-Impact Force for Pavement Breaking

Hydraulic breakers work by turning hydraulic energy into mechanical force using what's basically a carefully timed piston movement. When pressurized fluid pushes the piston up, then lets it drop down again, we're talking about forces between 8,000 to 15,000 kN per square meter according to Fluid Power Journal from last year. The piston hits the tool bit which cracks the pavement below. What makes these machines so effective is how they create controlled fractures in both concrete and asphalt surfaces. They need anywhere from 20% to 40% fewer passes compared to old fashioned mechanical hammers because today's systems transfer over 85% of their energy efficiently. That kind of performance difference really adds up on job sites.

Key Design Elements That Optimize the Performance of Hydraulic Breakers

Four engineering innovations enhance hydraulic breaker productivity:

- Dual-Speed Valves: Automatically adjust impact rates from 600–1,800 BPM based on material hardness

- Anti-Vacuum Chambers: Prevent cavitation damage during rapid cycling, extending service intervals by 200–400 hours

- Contour-Balanced Pistons: Reduce lateral vibrations by 55% (International Journal of Heavy Machinery, 2023)

- Auto-Lubrication Systems: Maintain optimal friction coefficients across temperatures from -20°C to 60°C

Energy Transfer Efficiency and Reduced Downtime in Continuous Operation

The latest generation of hydraulic breakers manages to transfer around 92% of their energy through this three stage shock wave system, which is way better than the old models that only managed between 68 to 74%. These machines come equipped with smart heat dispersion tech that lets them run non stop for eight hours straight without losing power, something that represents about a third more runtime compared to what was possible before. According to field testing, operators are seeing fuel savings of approximately 18 to 22 liters each day, all while still getting those reliable impacts ranging from 1.2 to 2.3 megajoules per hit on average. The numbers speak for themselves when it comes to how much these improvements matter in real world conditions.

Productivity Gains with Hydraulic Breakers in Real-World Applications

Measurable Time Savings in Road Demolition and Excavation Using Hydraulic Breakers

A study from the National Transportation Research Group in 2023 shows hydraulic breakers cut down road demolition time by around 30 to 50 percent when compared with old school jackhammer teams. These machines manage to smash through about 18 to 22 cubic yards of reinforced concrete every hour, which is roughly three times what manual workers can achieve. What's really impressive though is how they maintain super tight control near underground pipes and cables, working with precision down to the millimeter level. Because of this boost in productivity, many urban areas now finish those big weekend highway fixes during just one long night shift instead of stretching out over several days.

Case Study: Urban Pothole Repair Project Boosted by Hydraulic Breaker Deployment

One small town in the Midwest managed to speed up their pothole fixing work by around 60% once they started putting hydraulic breakers on their excavators. The crews basically stopped doing all that tedious saw cutting beforehand since they could just blast away the broken asphalt with controlled impacts. What used to take workers about 3 hours and 12 minutes now gets done in barely over an hour at each spot. And because of this time savings, maintenance teams can actually tackle nearly a quarter more road problems during every round of repairs they do throughout the area.

Data-Driven Analysis: 40% Faster Turnaround in Surface Rehabilitation Projects

Field data from 142 road resurfacing projects show teams using hydraulic breakers completed subsurface preparation 42% faster than those using pneumatic tools. The advantage comes from eliminating compressor setup and achieving 580–620 strikes per minute, versus 220–250 with air hammers. Contractors report daily outputs of 1.5 lane-miles, up from 0.9 miles with older methods.

Labor Cost Reduction and Fewer Equipment Mobilizations Per Job Site

Municipal departments using hydraulic breakers require 68% fewer workers per project than manual demolition crews. A 2023 Infrastructure Efficiency Report found the technology cut equipment transportation costs by 35% by reducing the need for auxiliary compressors and support vehicles—key factors in lowering per-mile rehabilitation expenses by $24–$28.

Common Road Maintenance Applications of Hydraulic Breakers

Breaking Asphalt Overlays and Concrete Patches With Precision

Hydraulic breakers remove deteriorated asphalt layers and repair concrete defects without damaging underlying substrates. Their controlled impact pulverizes surface irregularities while preserving adjacent pavement integrity, reducing material waste by 20–35% compared to traditional demolition hammers (Infrastructure Journal 2023).

Efficient Trenching for Utility Access During Roadway Upgrades

When upgrading water mains or electrical conduits beneath active roads, hydraulic breakers create clean trenches through compacted base materials. Properly sized attachments complete linear excavation 50% faster than backhoes in urban environments, minimizing traffic disruption.

Shoulder and Curb Repair Using Compact Hydraulic Breaker Attachments

Municipal crews use sub-1,000 lb hydraulic breakers to repair eroded road edges and reset displaced curbstones. Their compact design allows precise material removal around storm drains and signage posts—tasks previously reliant on manual labor.

Demolition of Aging Road Structures Prior to Resurfacing

From crumbling bridge approaches to cracked intersection slabs, hydraulic breakers efficiently fragment compromised concrete for loading and recycling. Their high-cycle operation removes 150–200 sq.yd of pavement per hour—three times the output of standard wrecking balls.

Evaluating Performance and Future Trends in Hydraulic Breaker Technology

Impact Rate, Blow Energy, and Stroke Length as Indicators of Efficiency

Hydraulic breakers today deliver their best results when certain engineering specs are met just right. When these machines hit impact rates above 1,800 beats per minute while delivering between 4,500 to 7,200 joules of force per blow, they can really tear through tough materials fast. According to the latest Construction Equipment Analysis from 2024, breakers whose stroke length matches project requirements within about plus or minus 5% actually cut down on fuel usage by around 15% when running nonstop. And there's another bonus too this level of accuracy cuts back on those annoying vibrations that tend to spread out and damage nearby pavement layers when doing focused demolition work.

Smart Hydraulics and IoT Integration for Predictive Maintenance

Top manufacturers are starting to install these fancy sensor packs that keep an eye on hydraulic pressure ranges from around 2,000 to 3,500 PSI plus track how fast those valves respond, usually under 0.12 seconds. What happens next? The collected data gets sent straight to these predictive maintenance dashboards where fleet supervisors can actually plan when parts need replacing instead of waiting for breakdowns. Some real world testing has shown pretty impressive results too - about 28 percent reduction in those unexpected repair halts when compared with older equipment models. This difference becomes even more noticeable during winter months when crews are working on removing stubborn asphalt from roads covered in ice and snow.

Eco-Friendly Designs Reducing Noise and Vibration Pollution

Next-generation breakers use nitrogen-charged dampening chambers to reduce operational noise to 82 dB(A)—40% quieter than decade-old models. Vibration-absorbing polymer mounts further reduce hand-arm vibration syndrome (HAVS) risks, meeting 2025 EU Directive 2019/1304 workplace safety standards. Early adopters in urban zones report 73% fewer noise complaints during overnight road repairs.

Trend Forecast: Increasing Adoption in Municipal Road Maintenance Fleets

Cities across the country have been swapping out their old pneumatic tools for hydraulic breakers, and this trend is growing fast - we're talking about around 19% each year according to Frost & Sullivan's latest report from 2025. Why? Well, when they actually look at the numbers over time, these hydraulic systems end up costing about 35% less per meter of road fixed compared to what they used before. For smaller jobs like fixing curbs along streets, most crews stick with the compact versions weighing between 150 to 350 kilograms. But when it comes to tearing down big chunks of concrete pavement, especially those massive slabs in parking lots or highways, contractors bring in the heavy hitters mounted on trucks that tip the scales at around 3,500 kg each.

FAQ

Q1: What are hydraulic breakers used for in road maintenance?

A1: Hydraulic breakers are used for breaking asphalt overlays, concrete patches, trenching for utility access, shoulder and curb repair, and demolishing aging road structures prior to resurfacing.

Q2: How do hydraulic breakers improve road maintenance efficiency?

A2: Hydraulic breakers improve efficiency by increasing daily output, reducing labor hours, minimizing material waste and noise levels, and providing precise control, which accelerates project completion times and reduces overall costs.

Q3: What are the environmental benefits of using hydraulic breakers?

A3: Hydraulic breakers are more fuel-efficient, reduce noise and vibration pollution, and result in fewer emissions, making them eco-friendly alternatives to traditional demolition methods.

Q4: How do modern hydraulic breakers minimize downtime?

A4: Modern hydraulic breakers incorporate design features such as dual-speed valves, anti-vacuum chambers, contour-balanced pistons, and auto-lubrication systems, which increase energy transfer efficiency and reduce maintenance requirements, minimizing downtime.

Q5: How is IoT technology integrated into hydraulic breakers?

A5: IoT technology in hydraulic breakers involves sensor packs that monitor hydraulic pressure and valve response speeds. Data is relayed to predictive maintenance dashboards, helping crews anticipate and address potential breakdowns, thus optimizing equipment uptime.

Table of Contents

- The Role of Hydraulic Breakers in Modern Road Maintenance

- Mechanical Principles Behind Hydraulic Breaker Efficiency

-

Productivity Gains with Hydraulic Breakers in Real-World Applications

- Measurable Time Savings in Road Demolition and Excavation Using Hydraulic Breakers

- Case Study: Urban Pothole Repair Project Boosted by Hydraulic Breaker Deployment

- Data-Driven Analysis: 40% Faster Turnaround in Surface Rehabilitation Projects

- Labor Cost Reduction and Fewer Equipment Mobilizations Per Job Site

- Common Road Maintenance Applications of Hydraulic Breakers

- Evaluating Performance and Future Trends in Hydraulic Breaker Technology

- Impact Rate, Blow Energy, and Stroke Length as Indicators of Efficiency

- Smart Hydraulics and IoT Integration for Predictive Maintenance

- Eco-Friendly Designs Reducing Noise and Vibration Pollution

- Trend Forecast: Increasing Adoption in Municipal Road Maintenance Fleets

- FAQ