Contact Info

FIRST FLOOR OF BUILDING 4, NO.1 TIELING NORTH ROAD, JINGXI, MINHOU, FUZHOU, CHINA

New York.

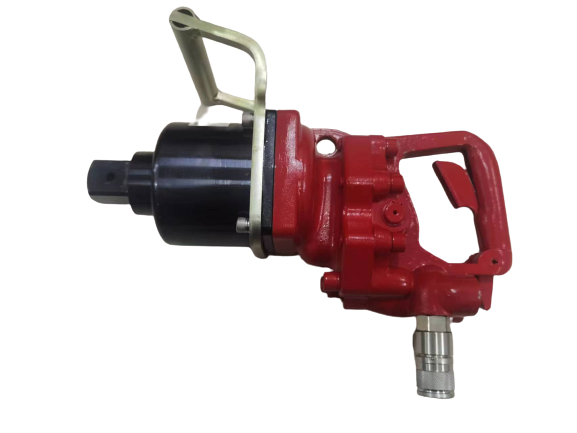

Electricity or mechanical power alone does not produce enough torque to operate heavy-duty hydraulic wrenches. The power supplied by hydraulics produces torque powerful enough to tighten or loosen large nuts and bolts. Such equipment are utilized in construction, automotive, and aerospace industries because proper fastening is important in those fields. Requiring heavy-duty performance, these electric wrenches are best suited with their robust design and adjustable torque.