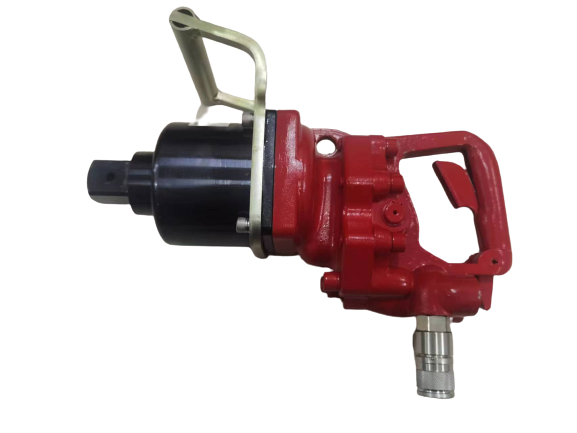

Hydraulic Impact Wrench: Tool for Bolt Handling

A hydraulic impact wrench uses hydraulic energy to convert into mechanical energy to generate a large torque for removing and installing bolts and nuts. It has features like large torque, simple operation, and high work efficiency. In the installation and maintenance of large mechanical equipment, DECKWELL's hydraulic impact wrenches can quickly and accurately complete the tightening and removal of bolts, shortening the maintenance and construction time.

Get A Quote