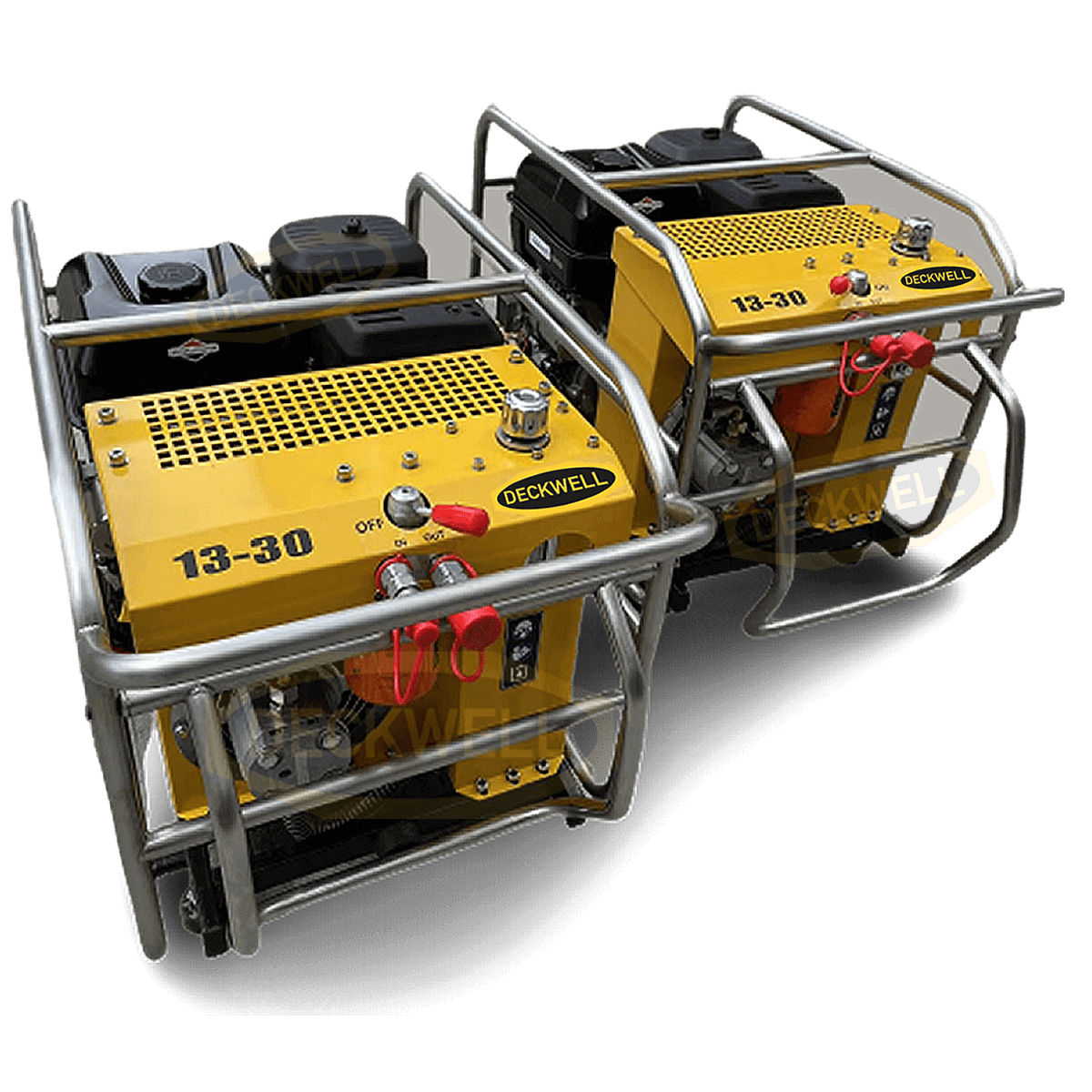

Hydraulic Power Unit: Core of Hydraulic Equipment

A hydraulic power unit is the core part that supplies power to various hydraulic devices. It consists of components like a motor, oil pump, oil tank, and control valves. The motor drives the oil pump to pressurize the hydraulic oil, and the high-pressure oil is sent to hydraulic actuators. DECKWELL's hydraulic power units are widely used in industries such as industrial production, construction engineering, and transportation, offering advantages like large output power, rapid response, and stable operation to meet different equipment's power needs.

Get A Quote