Contact Info

FIRST FLOOR OF BUILDING 4, NO.1 TIELING NORTH ROAD, JINGXI, MINHOU, FUZHOU, CHINA

New York.

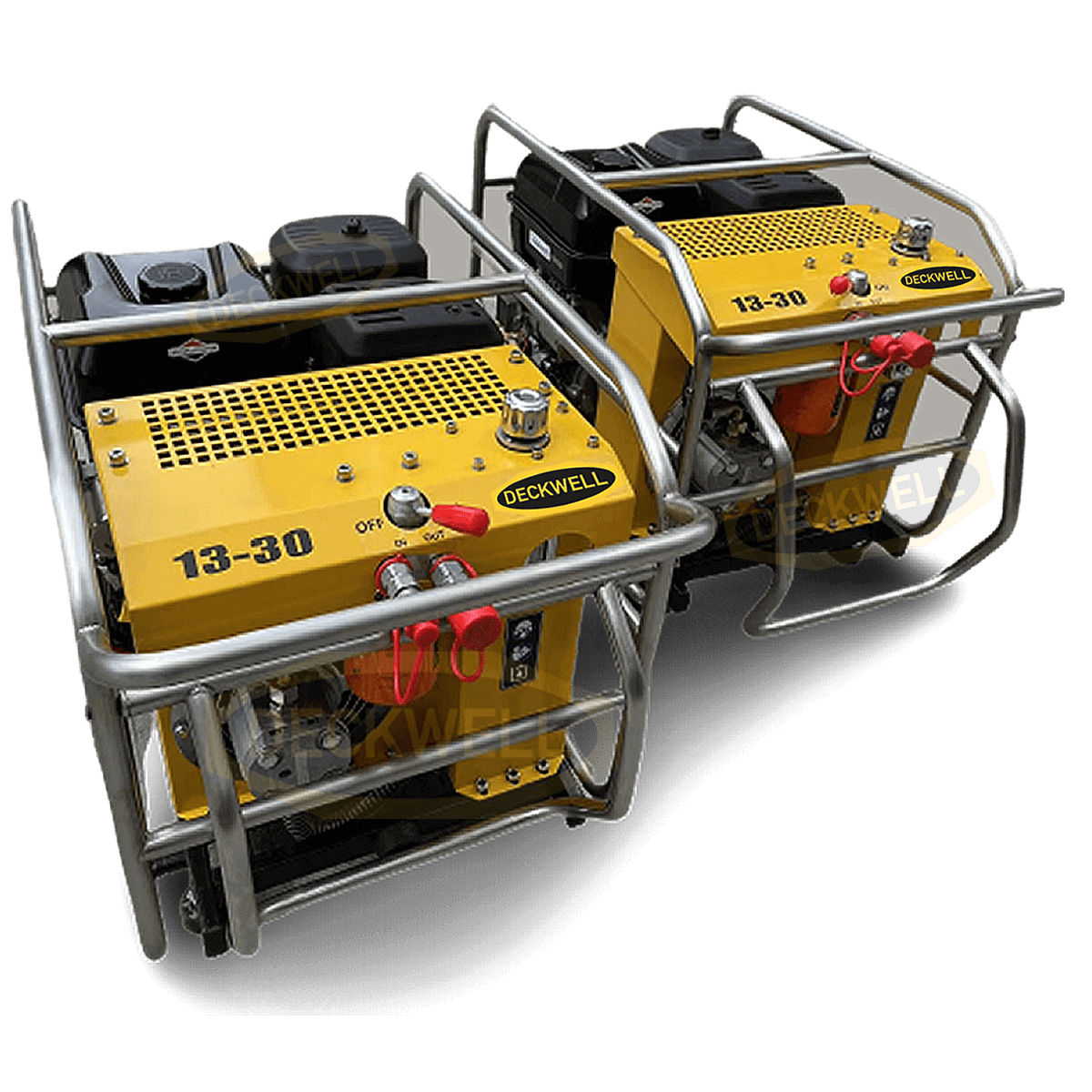

Hydraulic units aids firefighters in both rescue and firefighting operations. Components such as rescue spreaders which enable firefighters to un-jam doors, or artificial lifts for towering buildings are powered with it. It can function in harsh circumstances as it is made of high-quality materials. Some models permit rapid recharging which allows for non-stop working during prolonged fire scenarios. In order for the fire departments to perform their life-saving operations efficiently, these units need to be very dependable.