Precision and Control: Minimizing Urban Disruption with Hydraulic Breakers

Vibration and Noise Suppression in Dense Municipal Areas

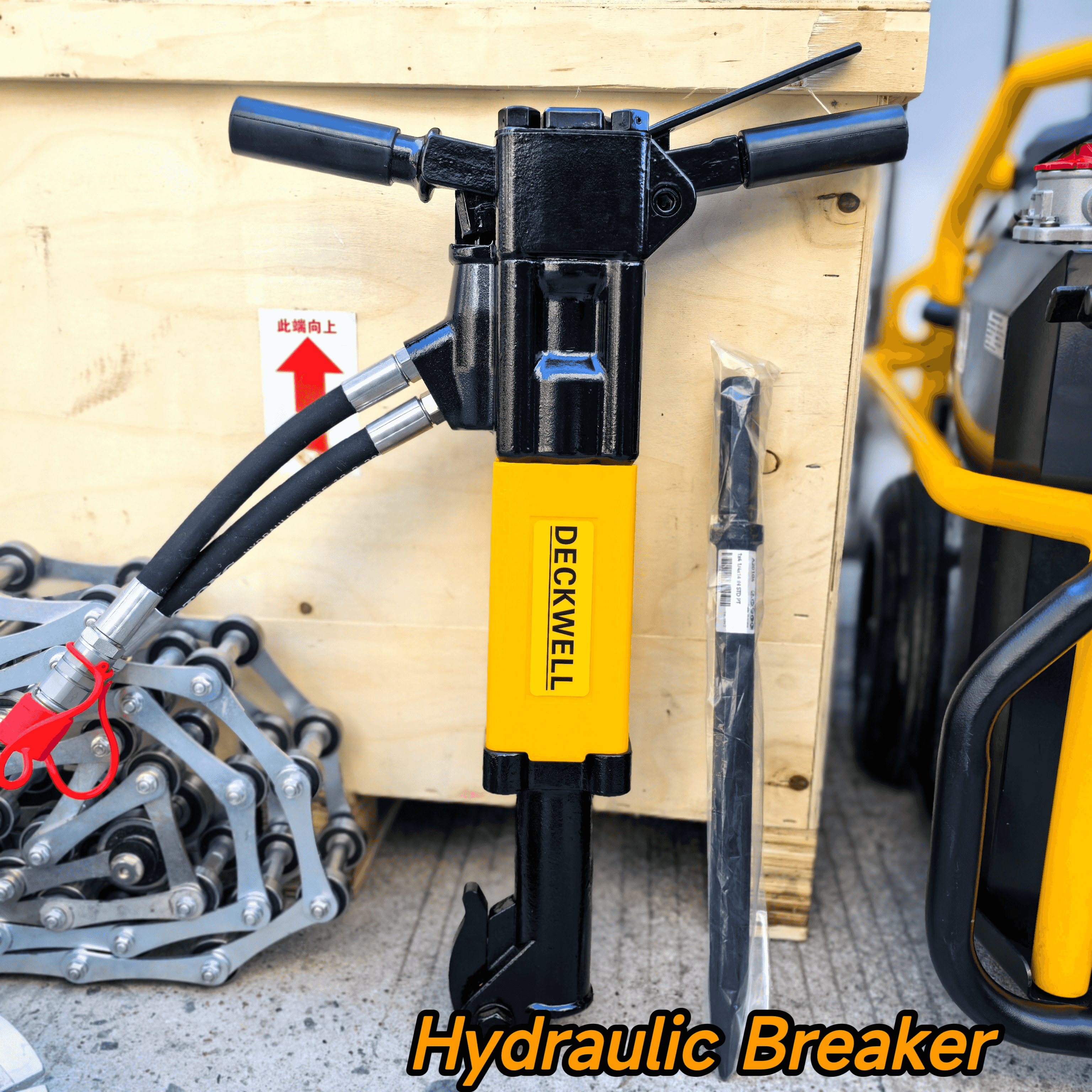

Hydraulic breakers today come equipped with special features that cut down on both noise and vibration, making them ideal for work in city environments. These machines operate at much lower frequencies than old fashioned pneumatic hammers, often under 15 Hz. This means they create about 80% less ground shaking around important areas like places where pipes run underground or near old buildings that need protection. The machines also have built in sound barriers that keep noise levels below 85 decibels, which helps cities follow all those noise rules from the EPA and local governments. When contractors use these systems, nearby buildings don't get tiny cracks from the vibrations, and neighbors aren't bothered as much during construction. According to a recent OSHA report from 2023, cities saw an amazing 92% drop in complaints about vibrations after switching to hydraulic breakers for removing sidewalks close to hospitals and schools.

Targeted Demolition Capabilities for Infrastructure-Sensitive Sites

In tight city spaces where every inch counts, hydraulic breakers offer pinpoint accuracy for targeted demolition work. The operators get to adjust both the impact power ranging from around 500 to 7,000 foot pounds and how often the breaker hits something between roughly 450 and 1,200 beats per minute. This lets them take apart things like old bridge connections or damaged sewer pipes without messing up surrounding infrastructure like pipes running underground or building foundations that are still in use. Blasting methods tend to cause way more unintended damage somewhere between 4 to 6 times worse based on what those DOT reports say, while these hydraulic tools let workers apply just the right amount of force needed for each job situation.

- Removal of single curb sections while preserving adjacent pavement

- Selective demolition of utility vaults within 6 inches of live gas mains

- Foundation extraction during building retrofits with <1 mm deflection in neighboring structures

This accuracy reduces remediation costs by approximately $47,000 per project, per the Municipal Infrastructure Journal (2023).

Versatile Municipal Applications: From Road Repairs to Utility Upgrades

Demolishing Pavements, Curbs, and Aging Bridge Elements

Municipal crews can take out old infrastructure with hydraulic breakers without messing up nearby buildings or causing major traffic problems. These machines deliver just enough punch to get the job done right while keeping damage to a minimum around underground pipes and support structures. According to some city renovation reports, this approach cuts down on repair bills by about 40 percent when compared to traditional demolition techniques. The accuracy really matters when working close to historic landmarks or newer developments where random blasts from heavy equipment could cause serious trouble for property owners and residents alike.

Enabling Trenchless Utility Installation and Retrofit Projects

Hydraulic breakers have become essential tools for modern infrastructure projects involving water lines, gas pipelines, and telecom installations. These machines can fracture concrete and asphalt with remarkable precision, making them ideal for trenchless work. With the right attachments, field crews punch through pavement to create access points for directional boring equipment. This means less mess on the surface and no need to dig up entire streets. Contractors report saving around 30% on time compared to traditional digging methods, plus avoiding those costly road closure fees. The technique works especially well when updating old utility systems under busy city streets. Think main roads where traffic would grind to a halt otherwise. By keeping roads open during repairs, cities actually cut down on emissions from stuck vehicles waiting in long lines. For municipalities dealing with aging infrastructure, this one-step process saves money in the long run while maintaining service continuity in densely populated areas.

Regulatory Compliance and Safety: Meeting Municipal Environmental Standards

Reduced Dust, Debris, and Ground-Borne Vibration for OSHA and EPA Alignment

When tearing down buildings in cities, there are strict rules about keeping the environment clean and making sure workers stay safe. That's why many demolition crews turn to hydraulic breakers these days. These machines come with built-in water sprays that cut down on dust so much that air quality stays way below what the EPA considers problematic. The way they deliver impacts also keeps rubble from spreading everywhere, which means less hassle getting permits later on. Ground shaking stays around 2.5 mm per second, comfortably under OSHA's 5 mm limit. This protects nearby pipes and building bases from damage during work. Real world experience shows contractors can get through inspections about 40 percent quicker when using these tools, avoiding those expensive stoppages. Plus, since they emit fewer pollutants, city officials appreciate how this equipment helps meet local green goals without sacrificing progress.

Hydraulic Breaker Advantages Over Traditional Alternatives in Cities

Why Blasting and Pneumatic Hammers Fail Under Urban Constraints

Blasting just doesn't work well in crowded city areas. According to industry standards like ISO 4866:2010, buildings need protection from vibrations below 5 mm/s, but typical blasting operations push past 12.5 mm/s easily enough to force people out of buildings and set up massive safety zones around the work area. Pneumatic hammers aren't much better either. They waste most of their energy, only getting about 30 to 40 percent of what hydraulic alternatives deliver. Plus, those big air compressors take up way more space on site than anyone wants. And let's not forget the oil mist these machines throw into the air at levels around 15 mg/m3, which pretty much guarantees problems with local air quality regulations. What really makes pneumatic tools problematic though is their inability to adjust on the fly when working near existing infrastructure. This lack of flexibility means they simply won't cut it in neighborhoods full of underground utilities or historic buildings where precision matters.

Operational Flexibility and Lower Total Cost of Ownership

Hydraulic breakers work really well in tight spots where space is limited, even in narrow alleys that measure less than 2.5 meters across. These machines pack around twice or triple the punch compared to similar pneumatic alternatives when it comes to impact energy. The way they're built allows workers to switch attachments quickly depending on what job needs doing next, whether it's breaking up concrete surfaces or digging trenches. Sure, buying one costs about 20 to 30 percent more upfront than going with traditional options, but most contractors find that these machines pay for themselves over time through reduced maintenance costs and increased productivity on site.

- 50% less fuel consumption

- 60% fewer annual maintenance hours

- Elimination of compressor logistics and associated labor

These efficiencies extend equipment service life by 3–5 years and drive down total cost of ownership—making hydraulic breakers the authoritative choice for forward-looking municipal fleets.

FAQs

Why are hydraulic breakers ideal for urban areas?

Hydraulic breakers operate at lower frequencies, reducing ground vibrations by about 80% and noise levels to below 85 decibels, which minimizes urban disruption.

How do hydraulic breakers help in targeted demolitions?

They provide precision with adjustable impact power and frequency, reducing unintended damage to nearby infrastructure and cutting remediation costs.

What makes hydraulic breakers environmentally friendly?

They come with water sprays to reduce dust, maintain air quality within EPA standards, and cause less debris spread, making them environmentally compliant.

What are the cost benefits of using hydraulic breakers?

Hydraulic breakers save municipalities around 40% on repair bills compared to traditional techniques and offer operational flexibility that reduces maintenance costs and increases productivity.

What are the advantages of hydraulic breakers over pneumatic and blasting methods?

They deliver higher impact energy efficiently, require less space, and do not cause issues like oil mist emissions, making them preferable for urban environments.

Table of Contents

- Precision and Control: Minimizing Urban Disruption with Hydraulic Breakers

- Versatile Municipal Applications: From Road Repairs to Utility Upgrades

- Regulatory Compliance and Safety: Meeting Municipal Environmental Standards

- Hydraulic Breaker Advantages Over Traditional Alternatives in Cities

-

FAQs

- Why are hydraulic breakers ideal for urban areas?

- How do hydraulic breakers help in targeted demolitions?

- What makes hydraulic breakers environmentally friendly?

- What are the cost benefits of using hydraulic breakers?

- What are the advantages of hydraulic breakers over pneumatic and blasting methods?