Core Operating Principle of Hydraulic Impact Wrenches

Hydraulic Pressure Conversion to High-Torque Rotational Impact

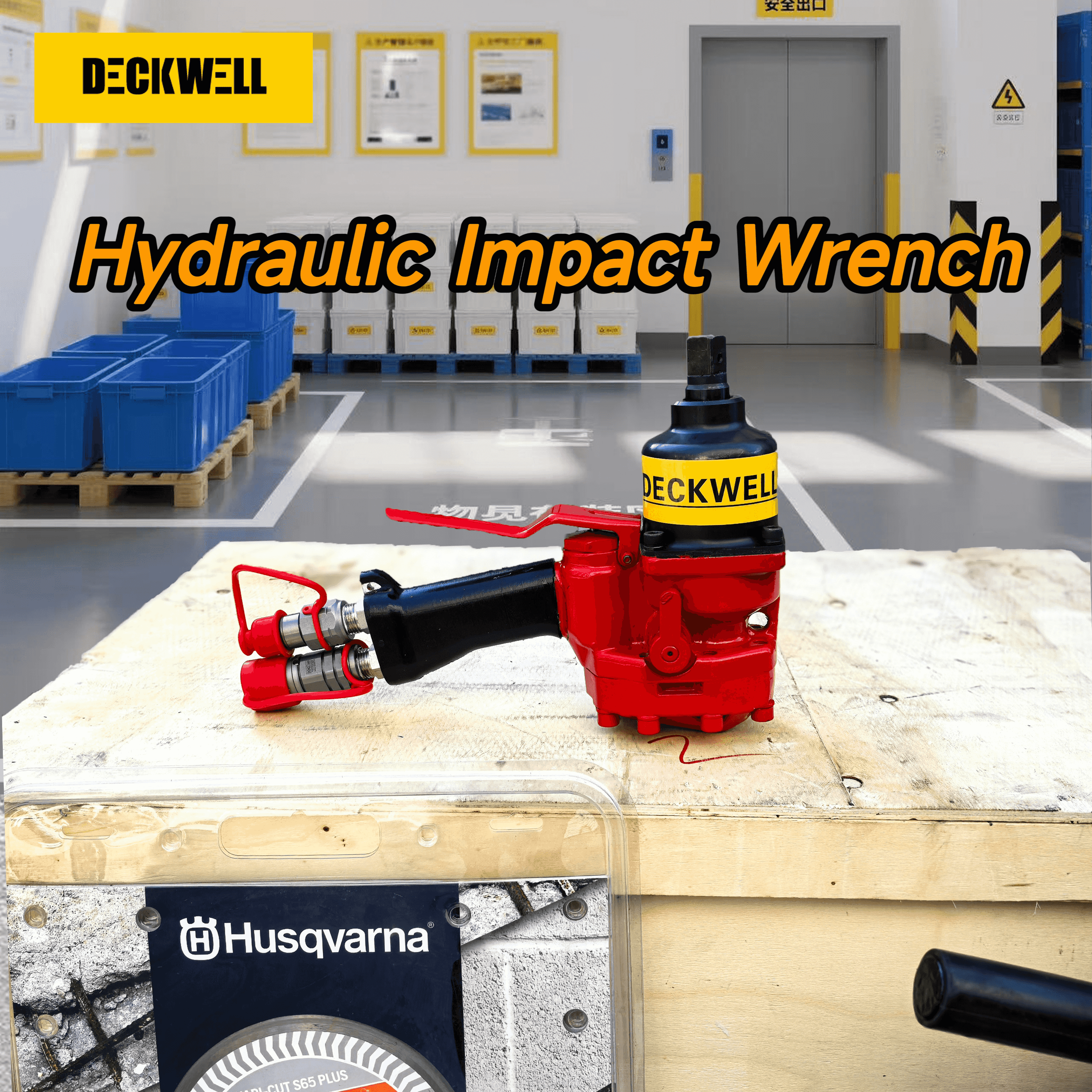

Hydraulic impact wrenches work by turning pressurized fluid into massive amounts of rotational force using several steps inside the tool. Inside these wrenches, there's a hydraulic motor that powers a hammer mechanism which hits an anvil repeatedly at around 1,200 to 2,500 times every minute. Each hit creates a sudden burst of torque that can reach as much as 1,200 Newton meters. What makes these different from regular drive tools is how they actually multiply the force applied while making it easier on whoever is holding them. This also helps prevent damage to tough bolts and screws because the impacts are so controlled. For rail workers especially, this efficiency means they can tighten track bolts and switch points according to EN 15308 standards without needing any extra power supply on site, which saves both time and money during maintenance operations.

Low-Recoil Design Benefits for Confined Rail Right-of-Way Environments

Hydraulic wrenches made specifically for rail work come equipped with counter rotating masses that soak up around 70% of the kickback force usually seen in pneumatic models. The reduced recoil makes all the difference when working in those cramped maintenance spaces that can be just over a meter wide or under train cars where every inch counts. These tools cut down on vibrations and keep the whole setup stable, which means bolts stay engaged properly and workers don't end up with sore wrists after hours of tightening. We're talking about a 45% drop in fatigue levels for technicians doing long shifts. Plus, their small footprint lets them reach into really tight spots like turnout mechanisms where bigger tools simply won't fit, making maintenance jobs faster and safer overall.

Rail-Specific Torque Demands and Compliance Requirements

Critical Fastening Applications: Track Bolts, Switch Points, and T&U Carriers

The integrity of rail infrastructure really comes down to three main fastening applications. First there are track bolts that hold rail joints together. Then we have switch points which allow trains to change direction. And finally, T&U carriers connect rail plates to sleepers. When connections aren't tightened enough, they can shift during train operations. On the flip side, tightening them too much might actually break the fasteners or damage surrounding materials. Either way, both situations increase the chances of derailments happening. That's why hydraulic impact wrenches are so important for delivering just the right amount of torque between 800 and 1,500 Newton meters. These tools help compress spring washers correctly while seating bolts properly in the ballast bed. The special impact action also protects against thread stripping on those hardened steel fasteners that face all sorts of challenges including constant vibrations, rust from moisture, temperature extremes from freezing and thawing, plus the weight of heavy train wheels passing over repeatedly. This protection helps maintain the track system's reliability year after year.

Standards Alignment: EN 15308 and ISO 16139 Torque Thresholds (850–1,200 N·m)

Following EN 15308 and ISO 16139 isn't just recommended but required for all railway fastening systems. The specs set torque limits ranging from around 850 to 1,200 Newton meters, and these numbers vary based on the specific fastener grade being used in different parts of the track. Getting within that ±3% accuracy window matters a lot because anything outside this range can lead to problems like track gauge widening, rail creep issues, or even complete joint failures when trains pass repeatedly over them. Today's hydraulic impact wrenches come equipped with digital sensors that record actual torque measurements as workers tighten bolts, matching those readings against what's specified in each job's work orders. This creates detailed records with timestamps that inspectors can check during audits. Maintenance teams need to regularly calibrate their equipment against official test benches to stay compliant. Why does this matter so much? Industry research shows that tracks installed without proper compliance see failure rates jump by about 40%, according to findings published in the Rail Engineering Journal last year.

Real-World Deployment of Hydraulic Impact Wrenches in Railway Infrastructure

Case Study: Major European Operator's Switch Point Bolting Efficiency Gains (2022–2023)

One of Europe's largest rail networks introduced hydraulic impact wrenches for securing switch points throughout their 2022 to 2023 maintenance cycle. These tools feature minimal recoil and exceptional precision, allowing workers to apply consistent torque even in the cramped spaces along train tracks where traditional methods struggle. Maintenance teams found they could complete each bolt connection about 40 percent faster compared to old pneumatic systems. Operators reported feeling less fatigued after long shifts too, with fatigue-related incidents dropping by nearly 30%. The biggest win? Fewer repeat visits were needed because connections stayed properly tightened without slipping below required levels. Every single installation hit the EN 15308 standard requirements for torque (between 850 and 1200 Newton meters). This not only keeps trains running smoothly but also ensures they stay within strict safety regulations set by transportation authorities across the continent.

Trend Analysis: Hydraulic vs. Pneumatic Adoption in EU and North American Track Renewal

Looking at how these tools are being adopted shows quite a difference between regions. European Union operators have been moving pretty strongly towards hydraulic impact wrenches when they need serious torque power. The numbers back this up too, with around 17% growth each year since 2020. Why? Well, these hydraulic models pack a better punch relative to their weight, don't need all that compressed air setup, and work great even in tough spots where there's lots of dust or grit. They last about twice as long before needing service compared to those old pneumatic ones. Meanwhile over in North America, most companies still stick with their pneumatic systems for roughly two thirds of their replacement work, probably because so many already have all the air supply equipment installed. But things are changing fast in certain areas where real heavy lifting matters. Take turnout assembly for example. Hydraulic wrenches here can hit over 1,100 Newton meters of torque, which beats what pneumatic tools offer by about 34%. That means faster job completion, more consistent results across different jobs, and ultimately saves money on repairs down the road.

FAQ

What are hydraulic impact wrenches used for in railway maintenance?

Hydraulic impact wrenches are used in railway maintenance to efficiently tighten track bolts, switch points, and T&U carriers to meet compliance standards like EN 15308, ensuring reliability and safety of rail infrastructure.

Why are hydraulic wrenches preferred over pneumatic models for rail work?

Hydraulic wrenches are preferred because they offer high-torque output with less recoil, making them ideal for use in confined spaces. They also require less maintenance and deliver consistent performance even in dusty or gritty environments.

What compliance standards do hydraulic impact wrenches help meet?

Hydraulic impact wrenches help meet compliance standards such as EN 15308 and ISO 16139, which specify torque thresholds for railway fastening systems, ensuring proper installation and reducing the risk of track failures.

How do hydraulic tools improve efficiency in railway operations?

Hydraulic tools improve efficiency by providing significant torque output with precision, reducing the time needed for maintenance tasks. This leads to fewer repeat visits and lowers fatigue among operators, boosting overall productivity.

What advantages do hydraulic wrenches offer over pneumatic ones in terms of lifespan?

Hydraulic wrenches generally have a longer operational lifespan compared to pneumatic ones, lasting about twice as long before needing maintenance. This results in cost savings and reduced downtime for repairs.

Table of Contents

- Core Operating Principle of Hydraulic Impact Wrenches

- Rail-Specific Torque Demands and Compliance Requirements

- Real-World Deployment of Hydraulic Impact Wrenches in Railway Infrastructure

-

FAQ

- What are hydraulic impact wrenches used for in railway maintenance?

- Why are hydraulic wrenches preferred over pneumatic models for rail work?

- What compliance standards do hydraulic impact wrenches help meet?

- How do hydraulic tools improve efficiency in railway operations?

- What advantages do hydraulic wrenches offer over pneumatic ones in terms of lifespan?