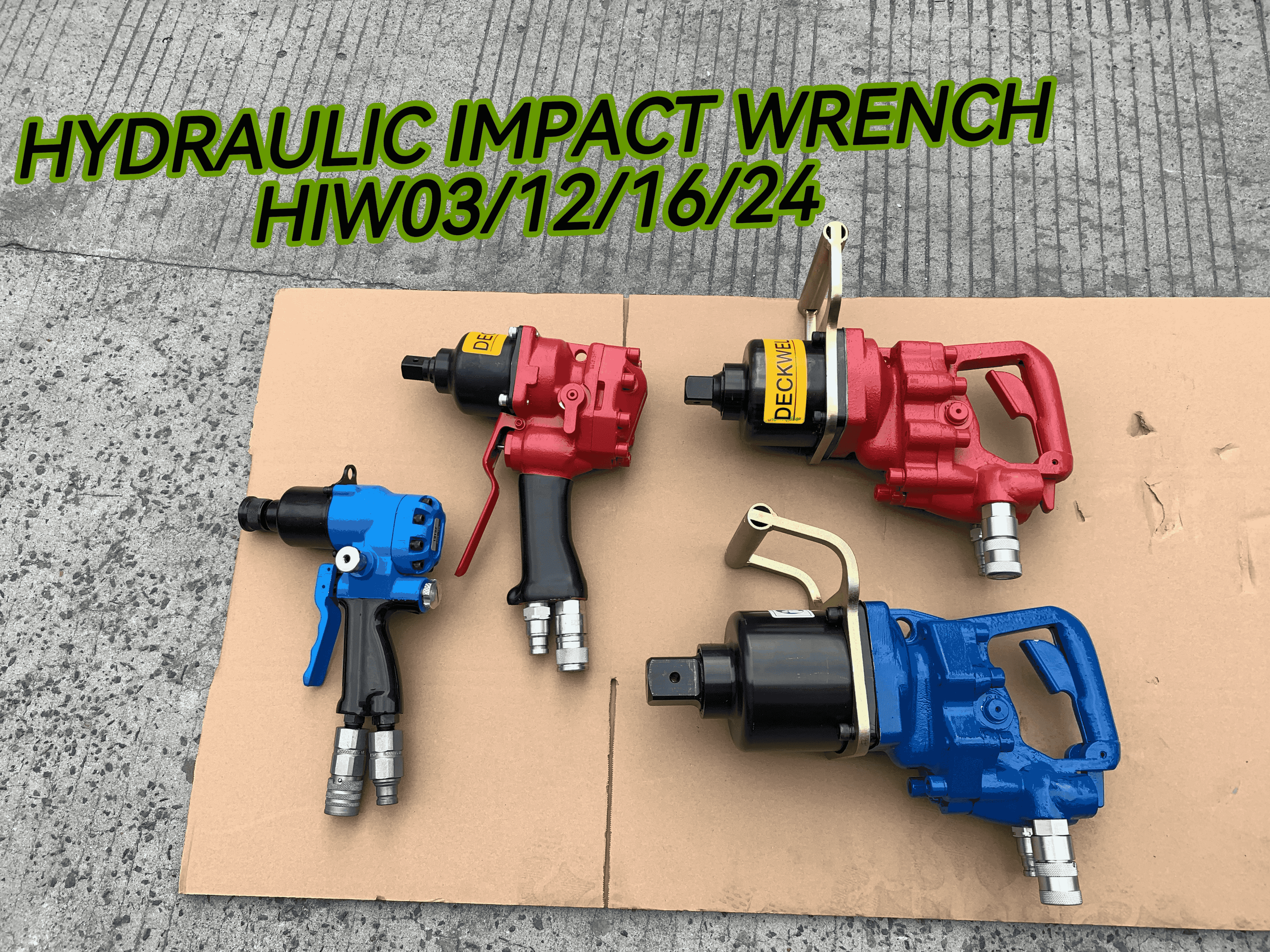

What is a hydraulic impact wrench and how it works in heavy-duty bolting

The hydraulic impact wrench works by turning pressurized fluid into spinning power using a special piston and hammer setup inside. These tools are different from air powered or electric versions because they rely on hydraulic systems that can push out pressure exceeding 70 MPa or around 10,000 psi. This makes them ideal for heavy duty jobs such as tightening bolts on large pipelines where flanges need to be connected securely. When the hydraulic oil moves through the unit, it pushes against a rotor component which then hits an anvil repeatedly. This back and forth motion helps loosen stuck nuts and bolts or applies just the right amount of twist needed for specific fastening requirements. The design includes reaction arms that take care of all those strong forces generated during operation so the tool doesn't slip away when working on important connections in industrial settings.

Torque output capabilities: Measuring performance up to 100,000 Nm

In really tough situations where torque needs hit between 25,000 and 100,000 Nm, these specialized tools shine. Think about applications like fastening those massive bucket teeth on mining excavators or holding together parts of offshore drilling rigs. Regular electric impact wrenches just can't cut it here since most top out around 3,500 Nm max. What makes high capacity hydraulic systems work so well? They use dual speed motors combined with gear reducers that basically multiply the force without making the whole tool enormous. The engineering behind this allows for serious power output while keeping the overall size manageable enough for actual field work conditions.

Key factors influencing power: Hydraulic pressure, flow rate, and system efficiency

Three variables dictate performance:

- Pressure (psi/bar): Dictates maximum force potential

- Flow rate (GPM/LPM): Determines rotational speed

- Mechanical efficiency: Gear quality and seal integrity reduce energy loss

For example, a 10 GPM system operating at 5,000 psi delivers 30% more usable torque than a 7 GPM system at the same pressure due to reduced fluid turbulence.

Torque accuracy, repeatability, and consistency in real-world applications

Today's hydraulic wrench models hold around 3% torque accuracy through 10,000 operations even when dirt and grime get into the mix. For those high risk connections on oil refinery valves, this kind of accuracy matters a lot. We've seen situations where bolts weren't tightened enough leading to serious leaks, each one running maintenance teams about $740,000 according to that Industrial Safety Report from last year. The good news? Most modern tools come equipped with internal pressure sensors plus automatic shut off features. These components work together so technicians get consistent tightening regardless of weather conditions or how experienced someone happens to be with the equipment.

Hydraulic vs. Pneumatic vs. Electric: Why Hydraulic Excels in High-Torque Applications

Performance comparison across power sources under extreme loads

When it comes to high torque jobs, hydraulic impact wrenches beat out both pneumatic and electric options hands down. These hydraulic tools can deliver power densities over 5000 psi consistently. Pneumatic tools depend on compressed air which starts losing effectiveness when pressure gets too high. Electric models tend to overheat once they reach around 20,000 Nm of torque. But hydraulic systems keep going strong past 50,000 Nm without dropping off. The reason? Fluid dynamics work differently here. There are no air pressure spikes or drops like with pneumatics, and no motor overheating issues either. That makes all the difference on tough jobs where reliability matters most.

Advantages of hydraulic systems in reliability, control, and force delivery

In industrial environments, hydraulic systems can deliver around 98% consistent torque accuracy because they use specially designed pumps and valves that control fluid flow as needed. These systems have a big advantage over other types of tools. Pneumatic ones need a steady stream of compressed air, while electric models often require cooling periods during operation. Hydraulic impact wrenches keep going even in tough conditions like those found on oil rigs when tightening bolts or maintaining mining equipment where downtime is costly. Looking at what researchers have found about how fluids behave under pressure, it turns out hydraulic tools can handle about 30% more work cycles compared to their electric counterparts before showing signs of wear and reduced effectiveness.

Limitations of pneumatic and electric impact wrenches in heavy-duty bolting

When it comes to pneumatic impact wrenches, they just can't maintain consistent torque past around 10,000 Nm because air gets compressed so easily. These tools need about two to three times the energy compared to hydraulic ones to get the same job done. Electric versions aren't much better either. The gearboxes start wearing out badly when going over 15,000 Nm, something we saw repeatedly in those mining equipment failures last year. What really sets hydraulic systems apart though is their ability to adjust pressure on the fly. They handle things like rusty bolts or materials expanding naturally during temperature changes without missing a beat. This kind of automatic compensation makes all the difference for safety critical work in places like nuclear plants where precision matters or when building bridges where structural integrity is everything.

Critical Applications in Oil & Gas, Mining, and Construction Industries

Bolt Tightening Challenges in Oil & Gas: Precision and Safety in Pipeline Flange Assembly

In the oil and gas sector, hydraulic impact wrenches tackle those tough bolting jobs nobody wants to mess up. Pipeline flanges need really precise torque control - around plus or minus 3% accuracy is what engineers look for to stop leaks when pressures get extreme. What these tools do best is spread the force evenly across big flanges that can be as wide as 72 inches. This matters a lot at refineries and out on offshore rigs where uneven pressure can lead to serious problems down the line. Recent safety reports from 2024 show something interesting too. Plants using hydraulic systems instead of old school manual wrenching have seen their bolt replacement rates drop by about 60%, especially in those harsh saltwater environments where corrosion eats away at metal faster than anywhere else.

Use in Mining and Construction Machinery: Durability Under Continuous Heavy Loads

The heavy machinery used in mining operations like shovels and tunnel boring machines needs specialized tools that can handle massive torque requirements over long periods. These tools must deliver around 40,000 Nm of torque throughout full 12 hour work shifts while maintaining their performance standards. Hydraulic impact wrenches are built to survive the brutal conditions underground where vibrations reach up to 12 g-force and dust levels often surpass 15 mg per cubic meter. They beat out pneumatic options in coal mines because they don't lose power in these harsh environments. What makes them reliable is the sealed lubrication system inside that keeps everything working smoothly even when installed at steep angles above 45 degrees during conveyor belt setups. This reliability means fewer breakdowns and less downtime for maintenance crews working deep below ground level.

Case Study: Offshore Platform Maintenance Using Hydraulic Impact Wrench for Bolt Removal

In a recent North Sea offshore operation, workers found that hydraulic impact wrenches could take out those tough M42 anchor bolts with 1,200 Nm preload much faster than old school methods. We're talking about cutting down the time by almost two thirds, which made a real difference on site. What really stood out was how these tools handled the reverse torque needed for those stubborn saltwater corroded flange joints rated at an impressive 690 bar pressure. The crew managed to reuse around 98% of all those bolts thanks to the controlled extraction forces, something that speaks volumes about the system's accuracy even in dangerous Zone 1 conditions where safety is always top priority.

Durability, Safety, and Smart Technology in Modern Hydraulic Impact Wrench Systems

Engineering for Longevity: Seals, Materials, and Wear Resistance in Harsh Environments

Today's hydraulic impact wrenches come equipped with chromium plated steel rods along with polyurethane seals capable of handling pressures well beyond 7,000 PSI. They also stand up pretty well against corrosion problems common in those harsh offshore conditions and mining operations where saltwater and dirt are constant threats. The good news for maintenance crews is these upgraded parts last roughly three times longer compared to regular materials when dealing with all sorts of grit and chemicals flying around construction sites. And don't forget about those dual seal systems either they keep fluids clean and working properly even after months of operation in dust filled environments where standard equipment would have failed long ago.

Safety Advantages Over Manual Tools in Hazardous Industrial Settings

Hydraulic systems eliminate manual force application, reducing musculoskeletal injury risks by 40% in refineries and construction sites compared to traditional wrenching methods (OSHA 2022). Closed-loop operation prevents sudden torque releases that cause slip-and-fall accidents, while ergonomic handles reduce operator fatigue during prolonged bolt-tightening sequences in confined spaces.

Digital Integration: Smart Sensors and Real-Time Torque Monitoring Trends

Leading models now feature IoT-enabled sensors that stream torque data to centralized dashboards, ensuring ±1.5% accuracy in critical applications like pipeline flange assembly. As noted in recent hydraulic technology studies, these systems predict seal failures 50–100 operating hours in advance by analyzing vibration patterns and hydraulic fluid viscosity changes.

Frequently Asked Questions

What is a hydraulic impact wrench?

A hydraulic impact wrench is a tool that converts pressurized fluid into spinning power to tighten or loosen bolts in heavy-duty industrial settings.

How does hydraulic power compare to pneumatic and electric tools?

Hydraulic tools excel in high-torque applications compared to pneumatic and electric tools because they can maintain consistent torque at higher pressure levels without overheating.

What industries commonly use hydraulic impact wrenches?

Hydraulic impact wrenches are commonly used in industries such as oil and gas, mining, and construction for tasks requiring precision and durability under continuous heavy loads.

Table of Contents

- What is a hydraulic impact wrench and how it works in heavy-duty bolting

- Torque output capabilities: Measuring performance up to 100,000 Nm

- Key factors influencing power: Hydraulic pressure, flow rate, and system efficiency

- Torque accuracy, repeatability, and consistency in real-world applications

- Hydraulic vs. Pneumatic vs. Electric: Why Hydraulic Excels in High-Torque Applications

- Critical Applications in Oil & Gas, Mining, and Construction Industries

- Durability, Safety, and Smart Technology in Modern Hydraulic Impact Wrench Systems

- Frequently Asked Questions