Road Construction and Rehabilitation: Asphalt and Concrete Breaking

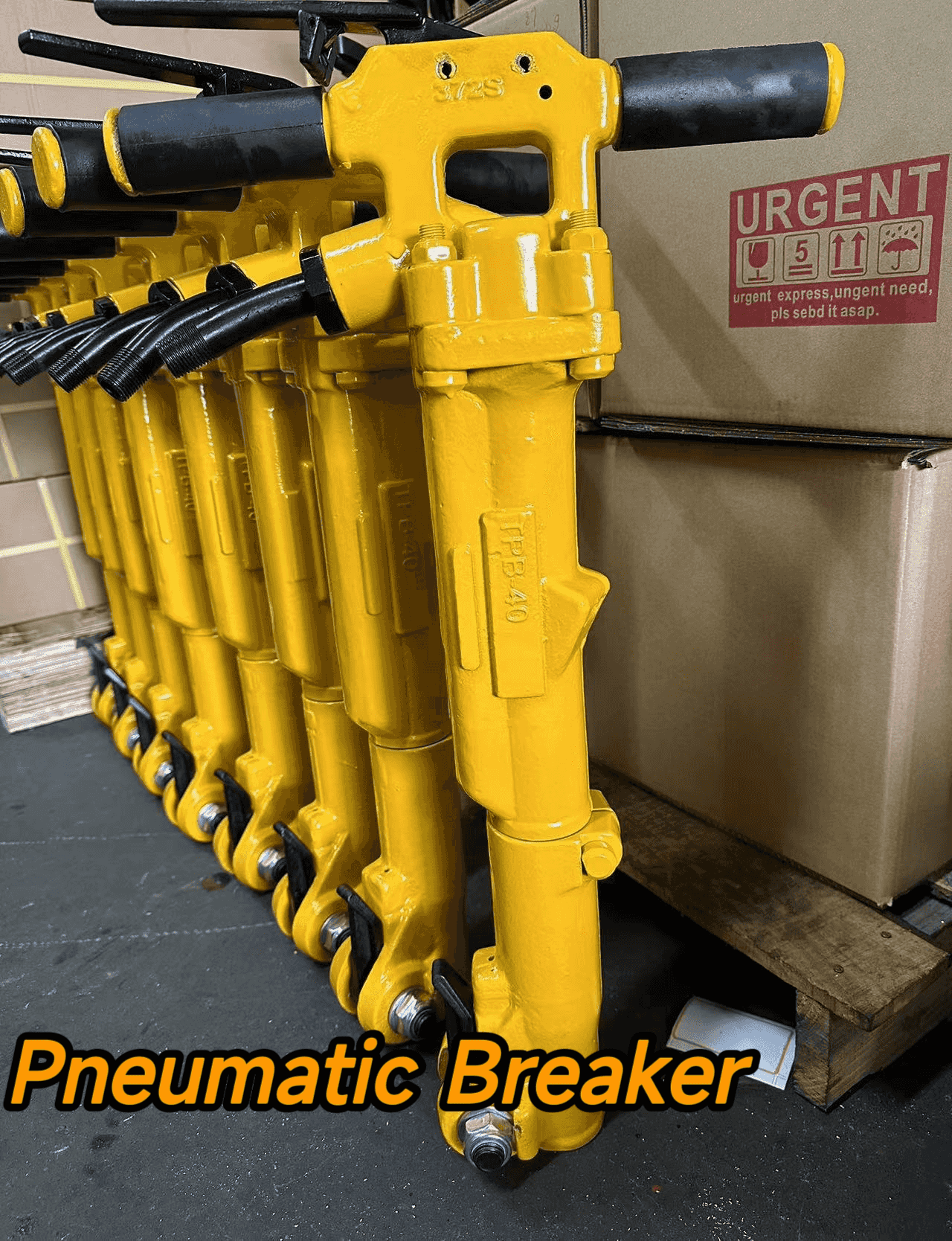

High-performance pneumatic breakers deliver essential power for road construction and rehabilitation projects, particularly when breaking through dense asphalt and concrete layers under demanding conditions. Their robust impact mechanism and precision control enable efficient material removal while meeting critical project constraints.

Breaking Dense Asphalt Layers Under Traffic Constraints

Getting roads fixed fast means taking out old asphalt quickly without causing too much traffic headache. Pneumatic breakers really stand out because they pack all that punch right where it needs to go on the surface. Operators can strip away those thick layers of asphalt way quicker compared to using regular jackhammers which take forever. The way these machines apply force in specific directions cuts down on unwanted vibrations that might crack nearby pavement. This actually lets crews keep at least part of the road open while working, so drivers don't have to detour completely around construction zones. Nobody wants to pay for shutting down entire streets when it's not necessary. Plus, newer models come equipped with special tech that quiets things down quite a bit, making them compliant with city noise rules even when crews need to work late into the evening hours.

Efficient Concrete Pavement Removal with Minimal Vibration Transfer

When tearing up concrete pavements, getting the right amount of force just right is really important so we don't damage what's underneath or mess with nearby pipes and cables. The newer air-powered breakers actually transfer about 40 percent less vibration than regular hydraulic ones because they hit differently and have those special handles that absorb some of the shock. Contractors can tweak how often the breaker hits based on how thick the concrete is and whether there are steel bars running through it. This helps keep neighboring slabs intact when only part of the pavement needs removal. According to actual job site measurements, workers report finishing slab removal tasks around 30% faster with these tools, plus there are far fewer tiny cracks left behind in whatever structure remains after demolition.

Comparison of Pneumatic Breaker Advantages in Road Projects:

| Performance Factor | Traditional Methods | High-Performance Pneumatic Breakers |

|---|---|---|

| Asphalt Removal Speed | 15–20 m²/hour | 35–50 m²/hour |

| Vibration Transfer | High (Risk to adjacent structures) | Low (Advanced dampening systems) |

| Traffic Disruption | Extended lane closures | Minimal through targeted precision |

| Concrete Slab Preservation | Frequent microfractures | Structural integrity maintained |

Structural Demolition: Controlled Concrete and Masonry Breakdown

Preserving Adjacent Structures During Urban Pneumatic Breaker Use

Getting demolition right in urban areas requires careful planning so neighboring buildings don't suffer damage from vibrations. The best pneumatic breakers for the job have adjustable impacts and special chisels that send most of their force straight down rather than sideways across the ground. Most experienced contractors follow a pattern where they start breaking away material furthest from delicate structures first. They also cut relief lines ahead of time to create sort of a shock absorbing zone between the work area and what needs protection. These days, most crews monitor vibrations constantly during demolition work, keeping them under 5 mm/s which is considered safe according to building codes. Some newer breakers come with built-in shock absorbers that cut ground shaking by around half compared to older equipment. When working close to historic buildings, many teams will use special low frequency breakers along with carbon fiber wraps on nearby walls. This extra precaution helps stop those tiny cracks from forming that can weaken old structures over time.

Managing Noise, Dust, and Confined-Space Challenges in Demolition

When working with pneumatic breakers in tight spaces, proper safety measures become absolutely essential. The noise problem gets tackled through special mufflers and silencer attachments that can bring down sound levels around 15 dBA. Contractors often set up temporary acoustic barriers right at the work site to keep noise contained where it matters most. For dust control, many modern setups feature water mist systems attached directly to the breaker tools themselves. These systems slash airborne particles by more than 90% according to OSHA standards. Down in basements or inside tunnels where space is limited, workers rely on portable ventilation equipment to keep air circulating while HEPA vacuum systems suck up all that dangerous silica dust. Safety remains top priority with gas detectors positioned near utility lines, lightweight breakers under 30 pounds making them easier to handle in cramped quarters, mandatory forced air respirators for protection, and wireless comms systems so teams can stay coordinated and prevent accidents from happening when dealing with rebar and other obstacles.

Site Preparation and Brownfield Redevelopment

Removing Reinforced Concrete Foundations with Heavy-Duty Pneumatic Breakers

When old factories get torn down to make way for something new, brownfield redevelopment turns those forgotten industrial spaces back into usable land. But there's always this tricky part about breaking apart those massive steel-reinforced concrete foundations. That's where heavy duty pneumatic breakers come in handy. They pack a serious punch without shaking everything around too much, which makes them great for cracking through really thick slabs sometimes as deep as two feet. The thing is, when environmental tests show possible contamination in the soil, we need to be careful about vibrations spreading pollutants around. These machines actually help achieve several important goals at once. First, they can chip away at reinforced concrete pretty efficiently. Second, they don't knock over nearby buildings or structures. And third, they work well even in cramped city spaces where room is limited. Getting the right equipment choice matters a lot because it keeps projects on schedule and makes sure the ground stays stable enough for whatever gets built next.

Utility Installation and Maintenance: Precision Excavation Near Critical Infrastructure

Safe Trenching Around Gas Mains, Fiber Optics, and Electrical Conduits

Using pneumatic breakers for precision digging helps avoid those dreaded utility line hits when working around important infrastructure. Workers can get really accurate measurements in tight city spaces by controlling the percussive force, usually keeping it below 50 foot-pounds of impact energy. This cuts down on vibrations that might otherwise travel to nearby gas lines or fiber optic cables. The Journal of Utility Safety reported back in 2023 that this approach slashes unexpected service interruptions by about three quarters compared to older methods. For jobs right next to active electrical conduits within 18 inches, there are special breakers designed to create minimal vibration while still breaking through concrete coverings. What we see at the end is faster access points for maintenance work with ground movement staying under a single millimeter, which means the underground utility systems stay intact and stable over time.

FAQ

What are high-performance pneumatic breakers used for?

High-performance pneumatic breakers are used in road construction and rehabilitation for efficient removal of dense asphalt and concrete layers. They are also utilized in structural demolition, brownfield redevelopment, and precise excavation around critical infrastructure.

How do pneumatic breakers minimize traffic disruptions during road work?

Pneumatic breakers minimize traffic disruptions by applying force in specific directions, which allows for faster asphalt removal and enables crews to keep part of the road open during construction, reducing the need for complete detours.

Why are pneumatic breakers preferred over traditional methods for concrete removal?

Pneumatic breakers are preferred due to their ability to transfer less vibration, maintain structural integrity of remaining slabs, and achieve faster removal rates with fewer microfractures compared to traditional methods.

How do contractors ensure safety while using pneumatic breakers near sensitive structures?

Contractors use adjustable impacts, special chisels, relief lines, and monitor vibration levels constantly to ensure safe operation near sensitive structures. They also utilize built-in shock absorbers and low frequency breakers for added safety.

What techniques are used to manage dust and noise during demolition?

Special mufflers, silencer attachments, water mist systems, and temporary acoustic barriers are used to manage dust and noise. Portable ventilation and HEPA vacuum systems help in confined spaces to ensure safety.

Table of Contents

- Road Construction and Rehabilitation: Asphalt and Concrete Breaking

- Structural Demolition: Controlled Concrete and Masonry Breakdown

- Site Preparation and Brownfield Redevelopment

- Utility Installation and Maintenance: Precision Excavation Near Critical Infrastructure

-

FAQ

- What are high-performance pneumatic breakers used for?

- How do pneumatic breakers minimize traffic disruptions during road work?

- Why are pneumatic breakers preferred over traditional methods for concrete removal?

- How do contractors ensure safety while using pneumatic breakers near sensitive structures?

- What techniques are used to manage dust and noise during demolition?